Iitreyi ze-acrylicziye zathandwa kakhulu kwiindawo zokuhlala nakwiindawo zorhwebo ngenxa yenkangeleko yazo entle, ukuqina kwayo, kunye nokuguquguquka kwayo.

Nokuba zisetyenziswa njengeetreyi zokuphakela kwindawo yokutyela ekumgangatho ophezulu, ukucwangcisa iitreyi kwindawo yodidi oluphezulu, okanye iitreyi zokuhombisa kwikhaya lanamhlanje, iitreyi ze-acrylic ezenziwe ngokwezifiso zinika umxube owahlukileyo wokusebenza kunye nomtsalane wobuhle.

Kodwa ngaba wakha wazibuza ukuba yintoni efunekayo ekudalweni kwezi zinto zenziwe ngokwezifiso? Kule khokelo ibanzi, siza kukubonisa yonke inkqubo yokwenziwa kwetreyi ye-acrylic eyenziwe ngokwezifiso, ukusuka kwingcamango yoyilo lokuqala ukuya ekuhanjisweni kokugqibela emnyango wakho.

1. Ingcebiso yoYilo kunye nokuQonda

Uhambo lwetreyi ye-acrylic eyenziwe ngokwezifiso luqala ngencoko.Ukubonisana ngoyilo linyathelo lokuqala elibalulekileyoapho umbono womthengi udibana nobuchule bomenzi.

Ngeli nqanaba, abathengi banokwabelana ngezimvo zabo, kubandakanya ubukhulu, imilo, umbala, kunye nazo naziphi na iimpawu ezithile abazifunayo, ezinje ngeendawo, izibambo, okanye iilogo ezikroliweyo.

Abavelisi badla ngokubonelela ngeetemplate zoyilo okanye basebenze nabathengi ukwenza iplani eyenziwe ngokwezifiso besebenzisa isoftware yoyilo oluncediswa yikhompyutha (CAD).

Le software ivumela ukulinganisa okuchanekileyo kunye nokubonwa kwe-3D, inceda abathengi ukuba babone imveliso yokugqibela ngaphambi kokuba kuqale imveliso.

Kwakhona linqanaba apho ubukhulu bezinto buchongwa khona—i-acrylic etyebileyo (3mm ukuya kwi-10mm) ifanelekile ukusetyenziswa kakhulu, ngelixa amaphepha amancinci (1mm ukuya kwi-2mm) esebenza kakuhle kwiitreyi zokuhombisa ezilula.

2. Ukukhetha Izinto: Ukukhetha i-Acrylic Efanelekileyo

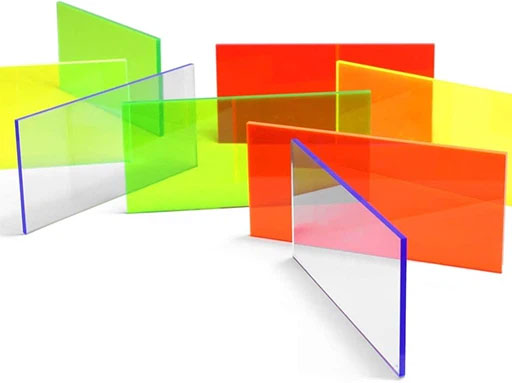

I-Acrylic, ekwaziwa ngokuba yi-PMMA (polymethyl methacrylate), iza ngeendlela ezahlukeneyo, kwaye ukukhetha uhlobo olufanelekileyo kubalulekile ekusebenzeni nasekubukekeni kwetreyi.

I-acrylic ecacileyo yeyona ndlela ikhethwa kakhulu ngenxa yokukhanya kwayo okufana neglasi, kodwa i-acrylic enemibala, i-acrylic eqhotsiweyo, kunye ne-acrylic ebonisiweyo ziyafumaneka kwiindlela ezizodwa.

Abavelisi bafumana amaphepha e-acrylic asemgangathweni ophezulu kubathengisi abathembekileyo ukuqinisekisa ukuqina nokuhambelana.

Ukumelana kwe-UV kwezinto zesixhobo yenye into ebalulekileyo, ingakumbi kwiitreyi ezisetyenziswa ngaphandle, njengoko zithintela ukuba tyheli ngokuhamba kwexesha.

Ukongeza, abanye abathengi bakhetha ukusebenzisa i-acrylic ephinda isetyenziswe ukuze ihambelane neendlela ezihambelana nokusingqongileyo, nto leyo ekhula ngokukhawuleza kwishishini lokuvelisa elenziwe ngokwezifiso.

3. Umzobo: Ukuvavanya uyilo

Ngaphambi kokuba kudlulelwe kwimveliso enkulu, ukudala iprototype kubalulekile ekuphuculeni uyilo kunye nokujongana nayo nayiphi na imiba enokubakho.

Ukucwangcisa iprototype kuvumela abathengi ukuba bahlole ubungakanani, imilo, kunye nokugqitywa kwetreyi ye-acrylic, benze uhlengahlengiso ukuba kuyimfuneko.

Besebenzisa uyilo lweCAD, abavelisi banokuprinta iprototype ye-3D okanye basike iqela elincinci le-acrylic besebenzisa i-laser cutter ukuze bafumane umfanekiso ochanekileyo.

Eli nyathelo libalulekile ekuqinisekiseni ukuba imveliso yokugqibela iyahlangabezana nolindelo lomthengi, nokuba yindawo efanelekile okanye umphetho ocoliweyo kakuhle.

4. Ukusika nokubumba i-Acrylic

Nje ukuba uyilo lugqityiwe, inkqubo yemveliso iqhubekela ekusikeni nasekubumbeni amaphepha e-acrylic.

Ukusika nge-laser yeyona ndlela ikhethwayo kwiitreyi ze-acrylic ezenziwe ngokwezifiso ngenxa yokuchaneka kwayo kunye nokukwazi kwayo ukwenza iimilo ezintsonkothileyo.

Umsiki welaser ulandela uyilo lweCAD, usika i-acrylic ngenkunkuma encinci kunye nemiphetho egudileyo.

Kwimilo enzima ngakumbi okanye imiphetho egobileyo, abavelisi banokusebenzisa ii-routers ze-CNC (Computer Numerical Control), ezinokubumba i-acrylic ngokuchanekileyo okuphezulu.

Eli nyathelo libaluleke kakhulu ekuqinisekiseni ukuba zonke izinto zetreyi—ezifana nesiseko kunye namacala—zihambelana ngokugqibeleleyo ngexesha lokuhlanganiswa.

5. Ukupholisha Umphetho: Ukufezekisa Isiphelo Esigudileyo

Imiphetho yetreyi ye-acrylic eluhlaza inokuba rhabaxa kwaye ingacaci, ngoko ke ukupolisha kuyimfuneko ukuze kufunyanwe ukugqitywa okukhazimlayo nokucacileyo. Kukho iindlela ezahlukeneyo zokupolisha imiphetho ye-acrylic:

Ukupolisha ilangatye:Indlela ekhawulezayo nesebenzayo apho ilangatye elilawulwayo linyibilikisa umphetho kancinci, lidale umphezulu ogudileyo nocacileyo.

Ukuhluza: Ukusebenzisa ivili elijikelezayo elineekhompawundi zokupolisha ukuze kube lula ukugudisa umphetho, kulungele amaphepha e-acrylic atyebileyo.

Ukupolisha ngokungcangcazela:Ifanelekile kwimveliso enkulu, le ndlela isebenzisa umatshini one-abrasive media ukupolisha iziqwenga ezininzi ngaxeshanye.

Umphetho ocoliweyo kakuhle awugcini nje ngokuphucula inkangeleko yetreyi kodwa ukwasusa naluphi na ubukhali, nto leyo eyenza kube lula ukuyiphatha.

6. Ukudibanisa: Ukuhlanganisa Konke

Kwitreyi ze-acrylic ezineecala, iindawo, okanye izibambo, ukuhlanganiswa linyathelo elilandelayo. Abavelisi basebenzisa isamente ye-acrylic (iglu esekwe kwisinyibilikisi) ukudibanisa iziqwenga kunye.

I-samente isebenza ngokunyibilikisa umphezulu we-acrylic, idale ubophelelo oluqinileyo, olungenamthungo xa lomile.

Ukulungelelaniswa ngononophelo kubalulekile ngexesha lokuhlanganiswa ukuqinisekisa ukuba itreyi ilingana kwaye ikwimeko entle ngokwesakhiwo. Iiklimpu zingasetyenziselwa ukubamba iziqwenga endaweni yazo ngelixa isamente iqina, nto leyo edla ngokuthatha iiyure ezimbalwa.

Ngokubaiitreyi ze-acrylic ezineempambo, imingxunya iyagqojozwa (ukuba ayikanqunyulwa ngexesha lesigaba sokubumba), kwaye izibambo zincamathiselwa kusetyenziswa izikrufu okanye iglu, kuxhomekeke kuyilo.

7. Ukwenza ngokwezifiso: Ukongeza iiLogo, imibala, kunye neeFinishes

Ukwenziwa ngokwezifiso yikona okwenza itreyi nganye ye-acrylic ibe yeyahlukileyo. Kukho iindlela ezahlukeneyo zokwenza itreyi ibe yeyakho:

Ukuzoba:Ukukrola nge-laser kunokongeza iilogo, umbhalo, okanye iipateni kumphezulu, nto leyo edala uyilo oluhlala luhleli nolusemgangathweni ophezulu.

Ukuprinta:Ukuprinta kwe-UV kuvumela uyilo olunemibala epheleleyo kwi-acrylic, efanelekileyo kwimizobo eqaqambileyo okanye iilogo zebhrendi.

Umzobo:Kwiitreyi ezinemibala, ipeyinti ye-acrylic okanye ipeyinti yokutshiza ingafakwa kumphezulu, kunye nengubo ecacileyo yongeziweyo ukuze ikhuseleke.

Ukuqandisa:Indlela yokuqhumisa isanti yenza ukugqitywa okungacacanga, okungacacanga kwitreyi okanye kuyo yonke, kongeza ubuhle.

Ezi ndlela zokwenza ngokwezifiso zinceda abathengi ukuba benze iitreyi ezihambelana nophawu lwabo okanye isitayile sabo sobuqu.

8. Ulawulo loMgangatho: Ukuqinisekisa ukuGqwesa

Ngaphambi kokuba ipakishwe, itreyi nganye ye-acrylic eyenziwe ngokwezifiso ihlolwa ngokungqongqo ngolawulo lomgangatho. Abahloli bajonga:

•Ubukhulu kunye nemilo efanelekileyo

•Imiphetho ethambileyo, ekhazimlisiweyo

•Iibhondi eziqinileyo nezingenamthungo kwiitreyi ezidibeneyo

•Imizobo okanye imifanekiso ecacileyo nechanekileyo

•Akukho mikrwelo, amaqamza, okanye iziphene kwi-acrylic

Naziphi na iitreyi ze-acrylic ezingahlangabezani nemigangatho yomgangatho ziyalungiswa okanye zilahlwe, ukuqinisekisa ukuba kuphela ziimveliso ezilungileyo ezifikelela kumthengi.

9. Ukupakisha kunye nokuthumela: Ukuhambisa ngononophelo

I-Acrylic ihlala ixesha elide kodwa inokukrwela lula, ngoko ke ukupakisha kakuhle kubalulekile.

Iitreyi ze-acrylic zigqunywe ngefilimu okanye iphepha lethishu ukuthintela imikrwelo, emva koko zifakwa kwiibhokisi eziqinileyo ezine-padding ukuze zingamonakalisi ngexesha lokuhamba.

Abavelisi basebenzisana namaqabane okuhambisa impahla athembekileyo ukuqinisekisa ukuhanjiswa kwayo ngexesha elifanelekileyo, nokuba kukuthunyelwa kwayo kwindawo yasekuhlaleni okanye kwamanye amazwe.

Ulwazi lokulandelela lunikezelwa kubathengi, nto leyo ebavumela ukuba bajonge inkqubela phambili yeodolo yabo ide ifike.

10. Inkxaso Emva Kokunikezelwa: Ukuqinisekisa Ukwaneliseka

Inkqubo yemveliso ayipheli ngokuhanjiswa.

Abavelisi abadumileyo banikezela ngenkxaso emva kokunikezelwa, bejongana nayo nayiphi na imiba enokuvela kwaye banike imiyalelo yokhathalelo ukunceda abathengi bagcine iitreyi zabo ze-acrylic.

Ukunyamekela ngokufanelekileyo—njengokucoca ngelaphu elithambileyo nesepha ethambileyo—kunokwandisa ixesha lokusetyenziswa kwetreyi, kuyigcine ibukeka intsha iminyaka emininzi ezayo.

Isiphelo

Ukudala itreyi ye-acrylic eyenziwe ngokwezifiso yinkqubo eneenkcukacha edibanisa ubuchule boyilo, iindlela zokuvelisa eziphambili, kunye nokugxila kumgangatho.

Ukususela kwingxoxo yokuqala ukuya ekuhanjisweni kokugqibela, inyathelo ngalinye lenziwa ngononophelo ukuqinisekisa ukuba imveliso yokugqibela ihlangabezana nombono womthengi kwaye idlula oko bekulindelwe.

Nokuba ufuna itreyi eyenzelwe wena okanye isipho esikhethekileyo, ukuqonda le nkqubo kunokukunceda wenze izigqibo ezinolwazi kwaye uxabise ubuchule obukwicandelo ngalinye.

Imibuzo Ebuzwa Rhoqo (FAQ) Malunga neeTrayi zeAcrylic ezenziwe ngokwezifiso

Yintoni umahluko phakathi kwee-Acrylic kunye neeGlass Trays?

Iitreyi ze-acrylic zikhaphukhaphu, aziqhekeki, kwaye zihlala ixesha elide kuneglasi, nto leyo eyenza ukuba zilungele ukusetyenziswa imihla ngemihla.

Zibonelela ngokukhanya okufana neglasi kodwa kulula ukuzenza ngokwezifiso ngemibala, imifanekiso ekroliweyo, okanye iimilo.

I-Acrylic ikwamelana nokutyheli kwe-UV ngaphezu kweglasi, nangona inokukrwela lula ukuba ayikhathalelwanga kakuhle.

Kuthatha ixesha elingakanani ukuvelisa itreyi ye-acrylic eyenziwe ngokwezifiso?

Ixesha liyahluka ngokobunzima boyilo.

Uyilo olulula olunobukhulu obuqhelekileyo luthatha iintsuku ezi-5 ukuya kwezi-7 zokusebenza, kuquka ukuvunywa koyilo kunye nemveliso.

Uyilo oluntsonkothileyo olunezicucu ezintsonkothileyo, iindawo ezininzi, okanye ukukrolwa okwenziwe ngokwezifiso kungathatha iintsuku ezili-10-14, oku kuthetha ukuba kukho iprototyping kunye nokulungiswa.

Ukuthunyelwa kongeza iintsuku ezi-2–5, kuxhomekeke kwindawo.

Ngaba iiTrayi zeAcrylic zingasetyenziswa ngaphandle?

Ewe, kodwa khetha i-acrylic engangeni kwi-UV ukuze uthintele ukuba tyheli elangeni.

Ziphephe iiqondo lobushushu ezigqithisileyo, njengoko i-acrylic inokugoba ngaphezulu kwe-160°F (70°C).

Iitreyi zangaphandle zilungele ukusetyenziswa kwiipatio okanye ecaleni kwechibi—aziqhekeki, zikhaphukhaphu, kwaye kulula ukuzicoca ngesepha namanzi athambileyo.

Ziziphi iindlela zokwenza ngokwezifiso ezikhoyo kwiitreyi ze-Acrylic?

Ezinye iindlela ziquka ukukrola nge-laser (iilogo, umbhalo), ukuprinta nge-UV (uyilo olunemibala epheleleyo), ukukhenkceza (ukugqitywa okungacwebezeliyo), kunye neemilo/ubukhulu obulungiselelwe wena.

Ungongeza iindawo, izibambo, okanye amaphepha e-acrylic anemibala.

Abavelisi badla ngokubonelela ngee-CAD previews ukuqinisekisa ukuba uyilo luhambelana nombono wakho ngaphambi kokuba uvelise.

Ndingayigcina njani itreyi ye-Acrylic ukuze ihlale ijongeka intsha?

Coca ngelaphu elithambileyo nesepha ethambileyo—phepha izinto zokucoca okanye zokucoca ezibangela imikrwelo.

Ukuba unebala eliqinileyo, sebenzisa ipolishi yeplastiki.

Gcina kude nezinto ezibukhali, kwaye uphephe ukubeka izinto ezinzima phezu kwazo ukuze zingagobi.

Ngokunyamekela ngokufanelekileyo, iitreyi ze-acrylic zinokuhlala iminyaka ngaphandle kokulahlekelwa kukukhanya kwazo.

I-Jaiyacrylic: Umenzi wakho oPhambili weTray ye-Acrylic eyenziwe ngokwezifiso eTshayina

I-Jayi acrylicyinkampani evelisa iitreyi ze-acrylic eTshayina. Izisombululo zetreyi ze-acrylic zikaJayi zenzelwe ukutsala abathengi kwaye zibonise izinto ngendlela enomtsalane. Ifektri yethu ineziqinisekiso ze-ISO9001 kunye ne-SEDEX, iqinisekisa umgangatho ophezulu kunye neendlela zokuziphatha zokwenza imveliso. Ngamava angaphezu kweminyaka engama-20 esebenzisana neebhrendi eziphambili, siyaqonda ngokupheleleyo ukubaluleka kokuyila iitreyi ze-acrylic ezikhulisa ukubonakala kwezinto kwaye zikhuthaze ulwaneliseko lokusetyenziswa.

Cebisa Ukufunda

Usenokuthanda nezinye iimveliso ze-acrylic ezenziwe ngokwezifiso

Ixesha lokuthumela: Agasti-13-2025